Ok ok ok… Leaving the crop where we have left after the last blog (CLICK HERE TO READ)

You in the meantime are probably by now safe and sound back in your warm house with a cupboard full of (impactful?) coffee.

So… You as a consumer are back home… We are still fighting Big Coffee and building an economic foundation to provide the coffee farmers with a sustainable living income, but…

Where in the process did we leave our beloved coffee farmers?

To make your favorite coffee accessible and easy to get on THIS side of the world, the coffee farmers on the OTHER side must run on a tight schedule all year long. Read more about what happens before the beans are being washed in the first blog.

After the hard work that is being done during the picking and harvesting the beans are being transported to the washing station. At the washing station, the coffee processing starts. Here coffee farmers separate the coffee cherry’s fruit flesh and skin from the beans. Yet, preserving the coffee’s profitability. This step is crucial to the quality and taste of your coffee: even if the coffee was picked perfectly ripe and the harvest has gone really well, poor coffee processing can lead to defects which decrease the value of the coffee.

And if the value of the coffee decreases… people don’t want to drink it anymore… go to other coffee brands… who spend lots of money on advertisements so they can easily catch the eye of the consumer… bombard them with george or brad… while our coffee rockstars suffer from this.

SO… The step of processing the beans, as actually all the other steps, is crucial to your coffee, and thus to the farmers.

There are several methods to process the coffee beans. And some processing methods require more time, investment and natural resources than others so choosing the right processing method can be a crucial decision for a coffee farmer and producer.

Our coffee farmers mainly use the wet processing method. This washing method is an expensive method but, even though it is expensive, it is the best way to get the highest quality cherries. The cherries are dunked into a pool of water upon arrival at the washing station. The ripe cherries sink to the bottom and the not ripe ones (or lower quality) float because of less density. Then the skin of the high-quality cherries is washed off. Since the washing station is of high importance in the process of transforming the high-quality bean to high quality coffee, AND as a gathering place, we ought to carefully invest in this aspect of our supply chain.

After washing and the removal of the skin of the bean, there is still another layer on top of the bean which is called mucilage. To remove this, the beans must ferment for quite some time. When the fermentation process is done the beans are rinsed and cleared by more water. Hereafter the beans are dried on new drying beds (improvement on drying technologies can allow for a lot less emissions. However, this is going to be a good discussion and in depth talk for another time) After the beans are dried, they are ready to be milled after which they can be roasted. In the same country. Jep. That is making radical changes. Leaving the deserved value where it is supposed to be left.

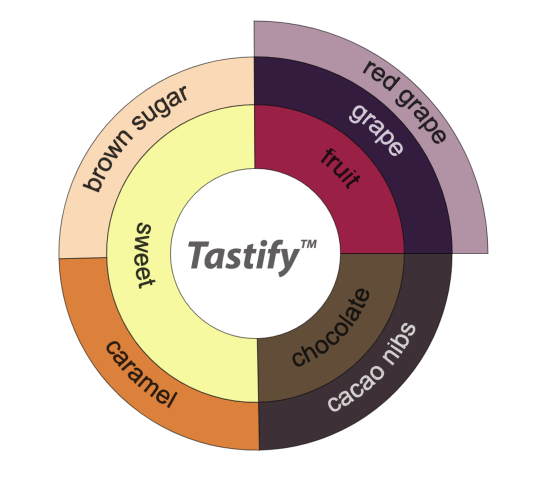

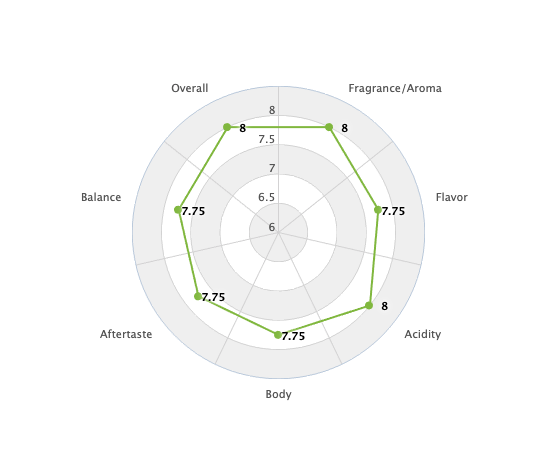

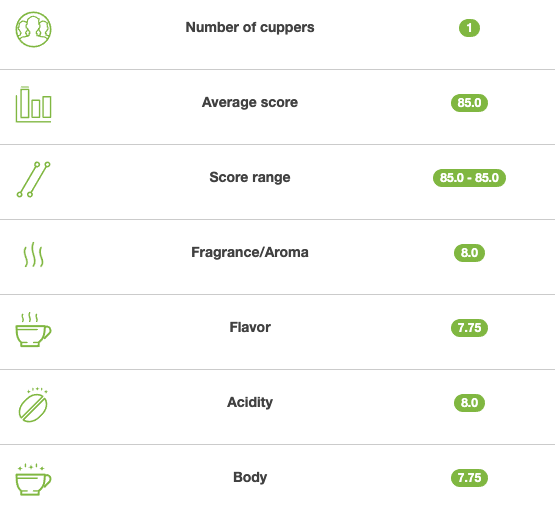

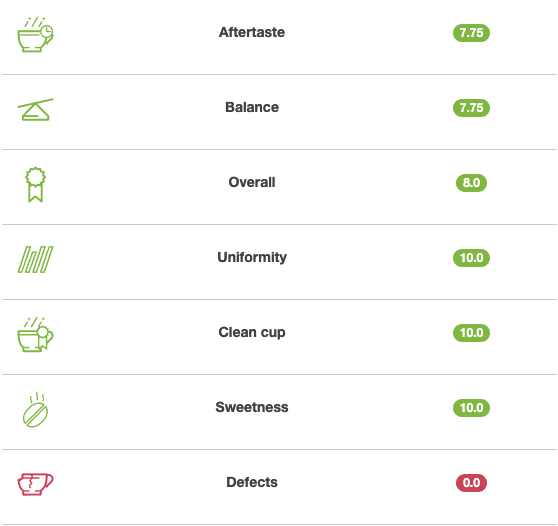

Roasting at the country of origin has a major impact on the economic systems of the countries. Since opening our roastery in Ethiopia we have been able to create a substantial number of jobs among which a great amount for women. Within the roasteries we have head roasters as well as quality checks so that every crop gives flavourful coffee.

Furthermore, more employment has been created in the transportation sector of our coffee as well as the employment that goes into the packaging of the coffee because after the coffee is being roasted, the beans are packaged in a bag which contains an air vent which allows the beans to breathe and air out. The beans must rest a bit before they are able to be used. In our case the beans must be transported to the Netherlands or various other locations by ship or by airfare. We aim to transport as much of our goods by air because of the diminished damage it brings to the environment.

Yes… Think about that again. 4 years, a lot of hard work, hot temperatures, possible risks, health hazards, stress, but also fun (!!!), measuring, experimenting, and transporting until you can enjoy that delicious, delightful and radical crop of coffee.

I hear what you are thinking… And…Indeed… No way spending a high amount of money on the latte art in your overpriced latte macchiato where 90% of that total coffee value disappears into the pockets of a handful of large multinationals. Called Big Coffee.

Yeek…

The money is screaming for the pockets of real rockstars! And of that of their families!

Moyee does 50 here, 50 there! As it should be. Next to the 20% FairChain premium and our living income program for the farmers we leave around 400% more money in the coffee producing country! And at the same time, you do not even pay more for your premium coffee, bi-winning!

And even better… You can now a whole year coffee for free! TRIPLE-WINNING!

Every crop helps. Drink Moyee, and make that sip count!

Our website uses cookies 🍪 but actually our model is a doughnut! 🍩 We'll assume you're ok with us using cookies to improve your browsing experience, but you can opt-out via thePrivacy Policypage if you wish.

Our website uses cookies 🍪 but actually our model is a doughnut! 🍩 We'll assume you're ok with us using cookies to improve your browsing experience, but you can opt-out via thePrivacy Policypage if you wish.